3D Printing Services

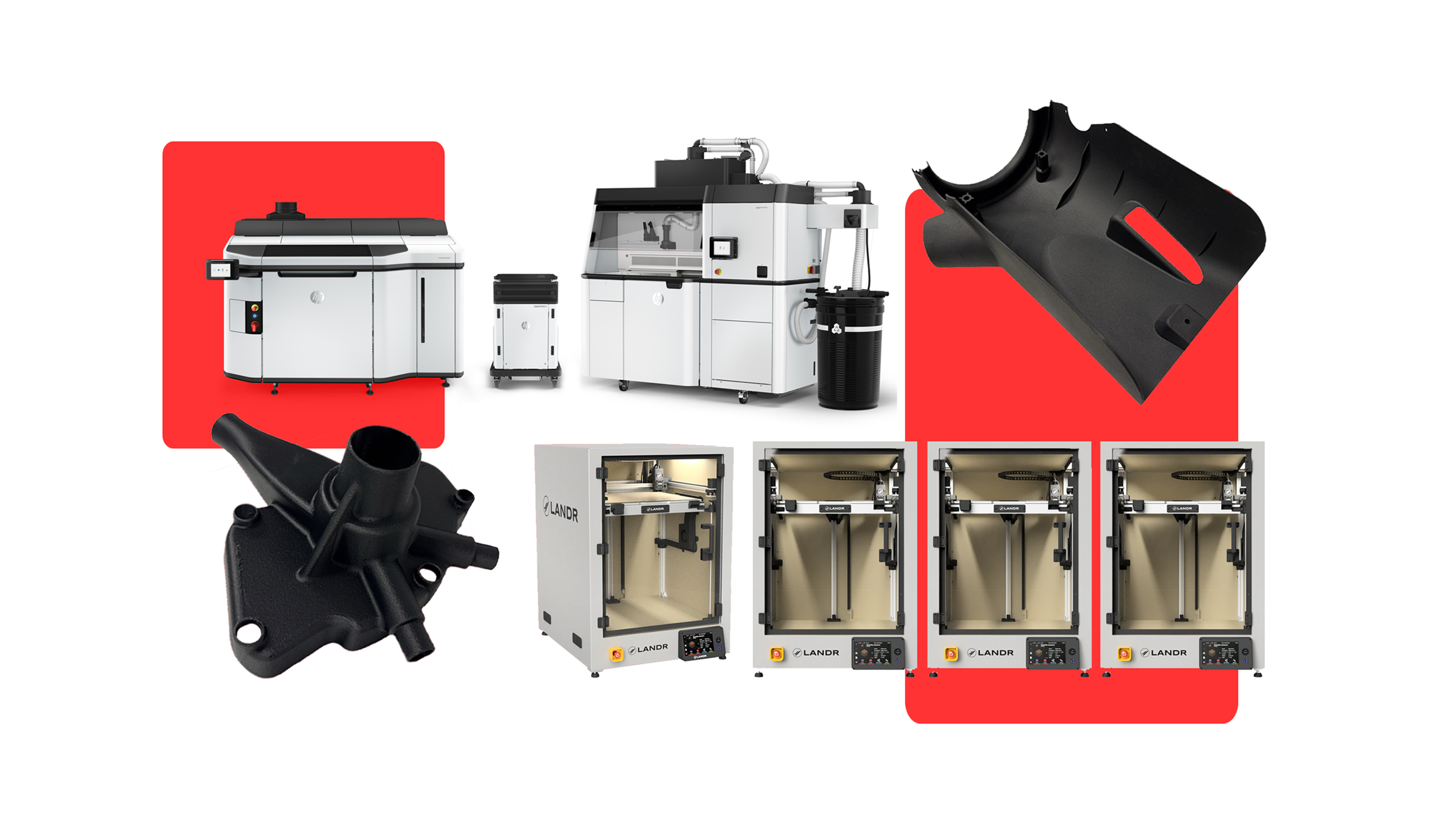

RYSE 3D delivers true production-grade additive manufacturing transforming 3D printing from a prototyping tool into a repeatable, scalable manufacturing solution. Using a combination of industrial FDM, HP Multi Jet Fusion (MJF), and Pellet Extrusion technologies, we produce functional, end-use polymer parts with precision, consistency, and cost-efficiency.

Our production services are designed to support every stage of manufacturing from low-volume pilot runs to full-scale serial production. With in-house expertise in material science, design for additive manufacturing (DfAM), and post-processing, RYSE 3D ensures every part meets the highest standards of mechanical performance, surface finish, and repeatability.

We operate a fleet of advanced machines across multiple platforms, capable of producing thousands of parts per week with full traceability and quality assurance all from our UK-based, Kings Award-winning production facility.

MJF - PA12, PA11 High detail Parts

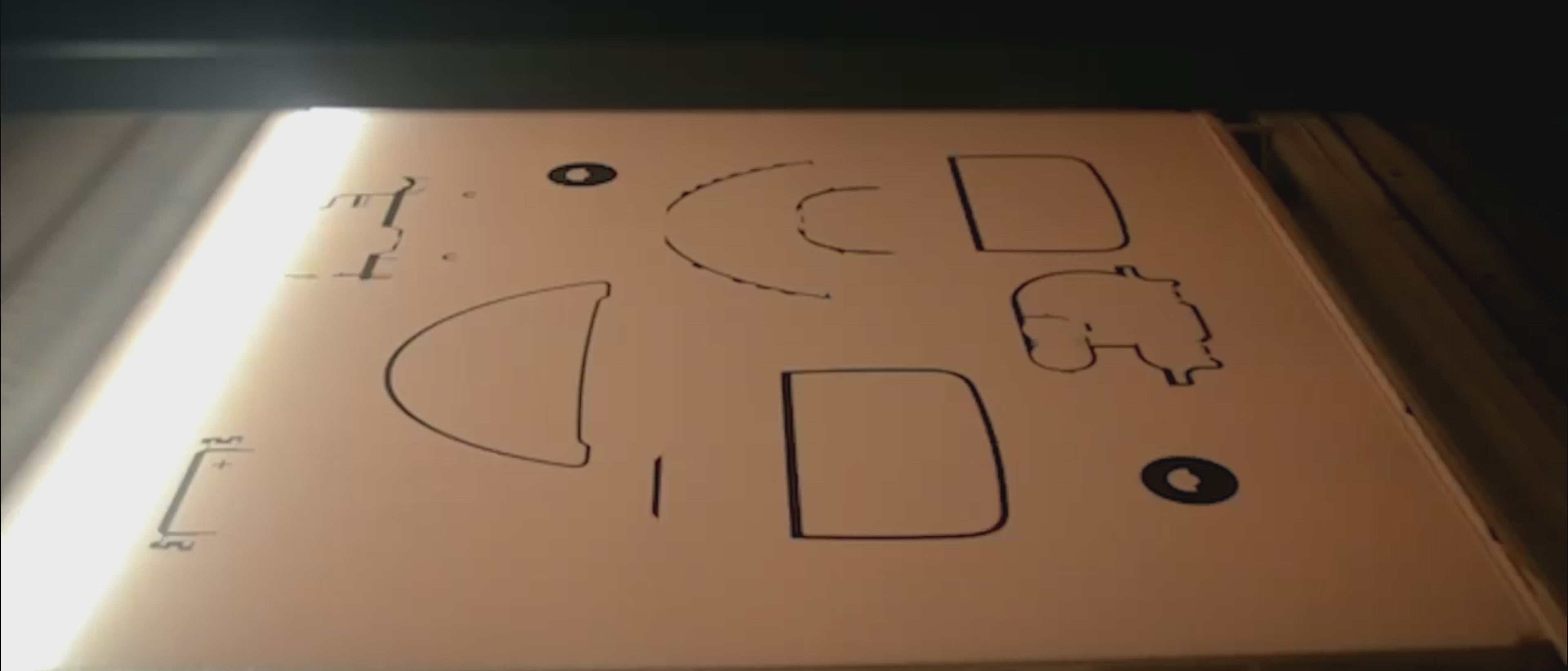

Our MJF (Multi Jet Fusion) production line delivers high-precision, end-use polymer parts using advanced HP additive-manufacturing technology. It’s designed for customers who need accurate, repeatable, and production-ready components straight off the printer.

At RYSE 3D, we run HP PA11 and PA12 materials to suit a wide range of functional applications:

- PA 11 (Bio-based Nylon 11) – High ductility, excellent impact resistance, and superior fatigue performance. Ideal for automotive interiors, snap-fit parts, protective housings, and flexible clips.

- PA 12 (Nylon 12) – Outstanding dimensional stability, fine surface finish, and durability under load. Perfect for enclosures, manifolds, tooling, and low-volume production parts.

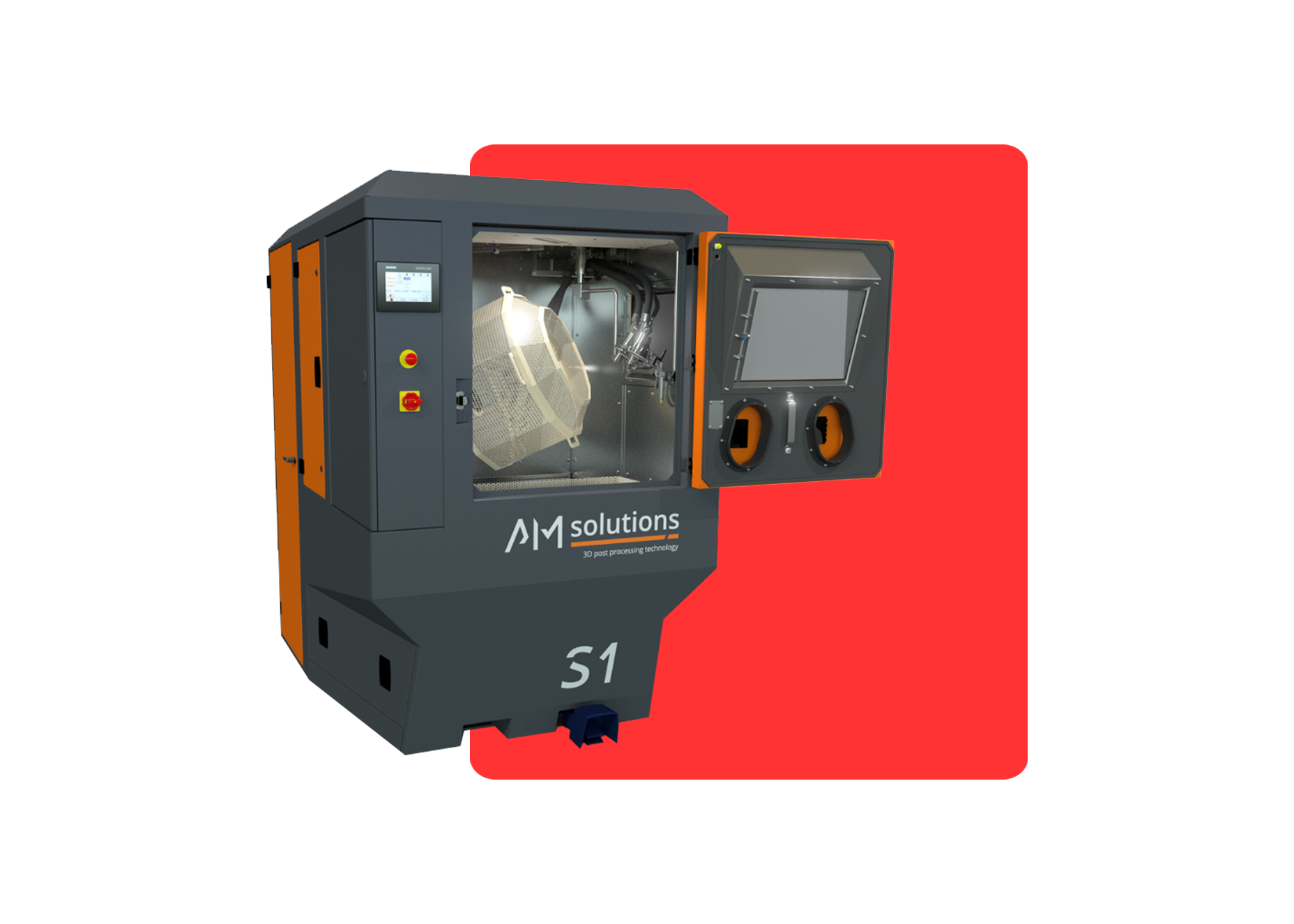

Our in-house finishing options include bead blasting, dyeing, vapour fusing, machining, and inspection, ensuring every component meets production standards.

Max Part Size 380 x 380 284mm

⚙️ Key Features of HP MJF 3D Printing

- High-detail, isotropic parts with exceptional dimensional accuracy

- Production-grade materials - PA11 and PA12 for strength, flexibility, and durability

- Consistent quality at scale - ideal for low to high-volume manufacturing

- Smooth, semi-matte surface finish straight off the build

- Excellent mechanical performance with minimal post-processing

- Design freedom for complex geometries and consolidated assemblies

- Fast turnaround times with full in-house production and finishing

- Made in the UK - backed by the King’s Award for Enterprise in Innovation

FDM - High Performance Large Fromat Parts

At RYSE 3D, our FDM manufacturing service uses Industrial printers to produce strong, functional parts directly from CAD data with no tooling or long lead times. Ideal for prototypes, jigs, fixtures, and full-scale production components.

We print in ABS, ASA, PETG, Nylon (PA6, PA-CF, PA-GF), Polycarbonate, and TPU + more, as well as recycled pellet materials for sustainable, high-volume output.

Whether it’s carbon-fibre tooling, durable housings, flexible seals, or structural automotive parts, our FDM process delivers tough, production-ready results at a fraction of the cost of traditional manufacturing.

Max Part Size 500 x 500 x 700mm

⚙️ Key Features of FDM 3D Printing

- Industrial-grade strength and durability using advanced polymers such as PA12-CF, PA6-CF, ASA-CF, PETG-CF, and TPU

- Large-format build capability for functional, structural, and end-use parts

- Exceptional dimensional stability with tight tolerances and strong layer adhesion

- Versatile material options covering high strength, flexibility, and heat resistance

- Optimised surface finish with post-processing options including vapour smoothing and polishing

- Cost-effective manufacturing for prototypes, tooling, and production components

- Rapid lead times with full in-house printing and finishing capability

- Proudly made in the UK — precision-built and quality-assured by RYSE 3D

Discover Post Processing

Explore RYSE 3D’s full range of post-processing services engineered to deliver parts that look, feel, and perform like final products.

3D Scanning & Reverse Engineering

Explore RYSE 3D’s 3D Scanning and Reverse Engineering services bringing physical components back to life in the digital world.

Still have some questions?

Work with RYSE 3D’s specialists to turn your designs into production-ready parts. From material advice to scalable manufacturing, our team will help you make stronger, faster, and more efficient with HP Multi Jet Fusion.