Post Processing

At RYSE 3D, we go beyond printing. Our advanced post-processing suite transforms 3D-printed components into production-grade parts with superior surface quality, mechanical performance, and visual finish. Every process is engineered to meet the standards expected from injection-moulded or machined components ensuring that every part we deliver is ready for assembly, presentation, or end use.

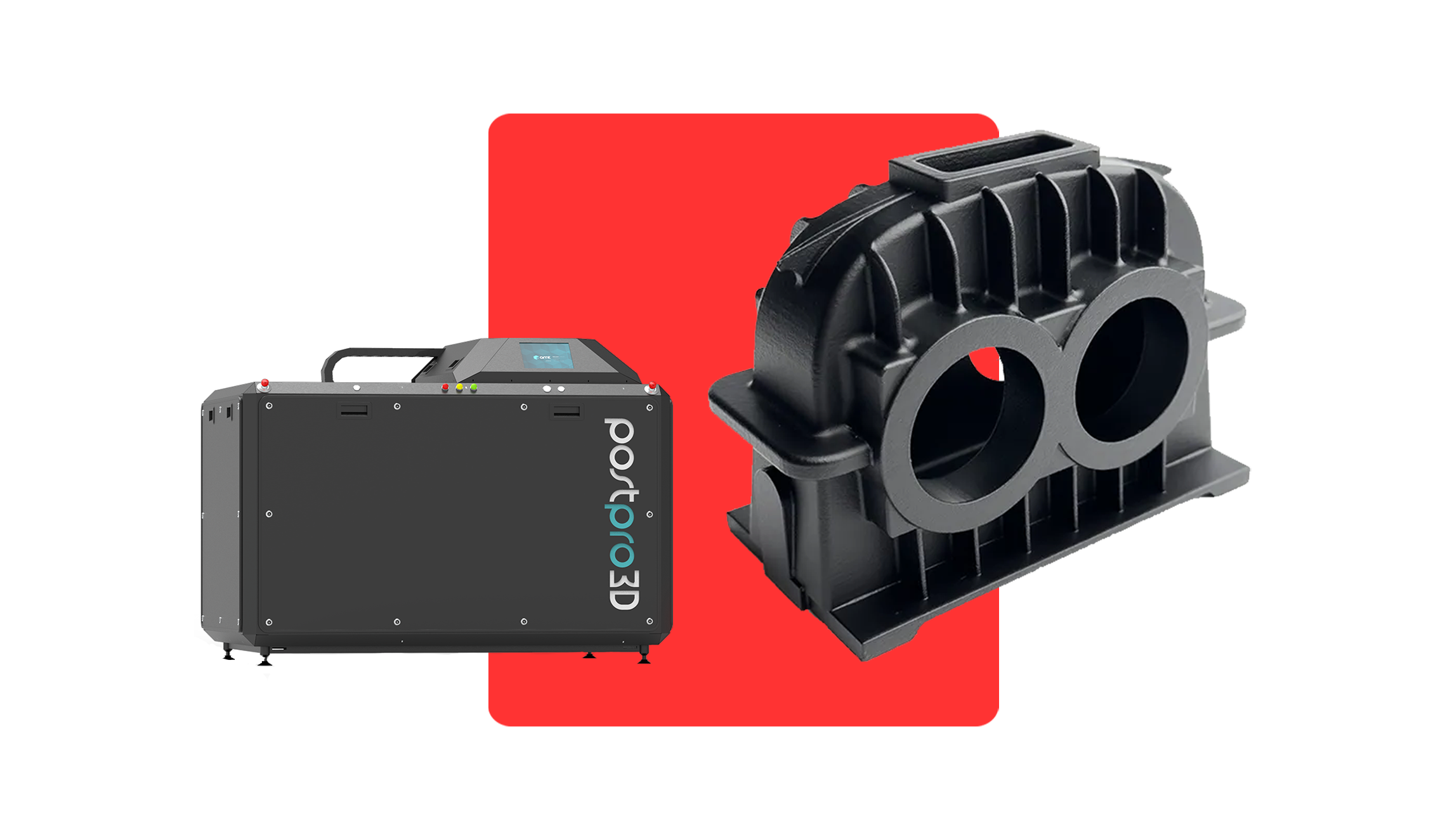

💨 Vapour Smoothing

Our vapour smoothing process uses a controlled solvent vapour to chemically fuse the outer layer of polymer parts, sealing the surface and eliminating visible layer lines. The result is a glossy, sealed, and near-injection-moulded finish that enhances aesthetics, durability, and liquid resistance — ideal for consumer products, automotive interiors, and watertight components.

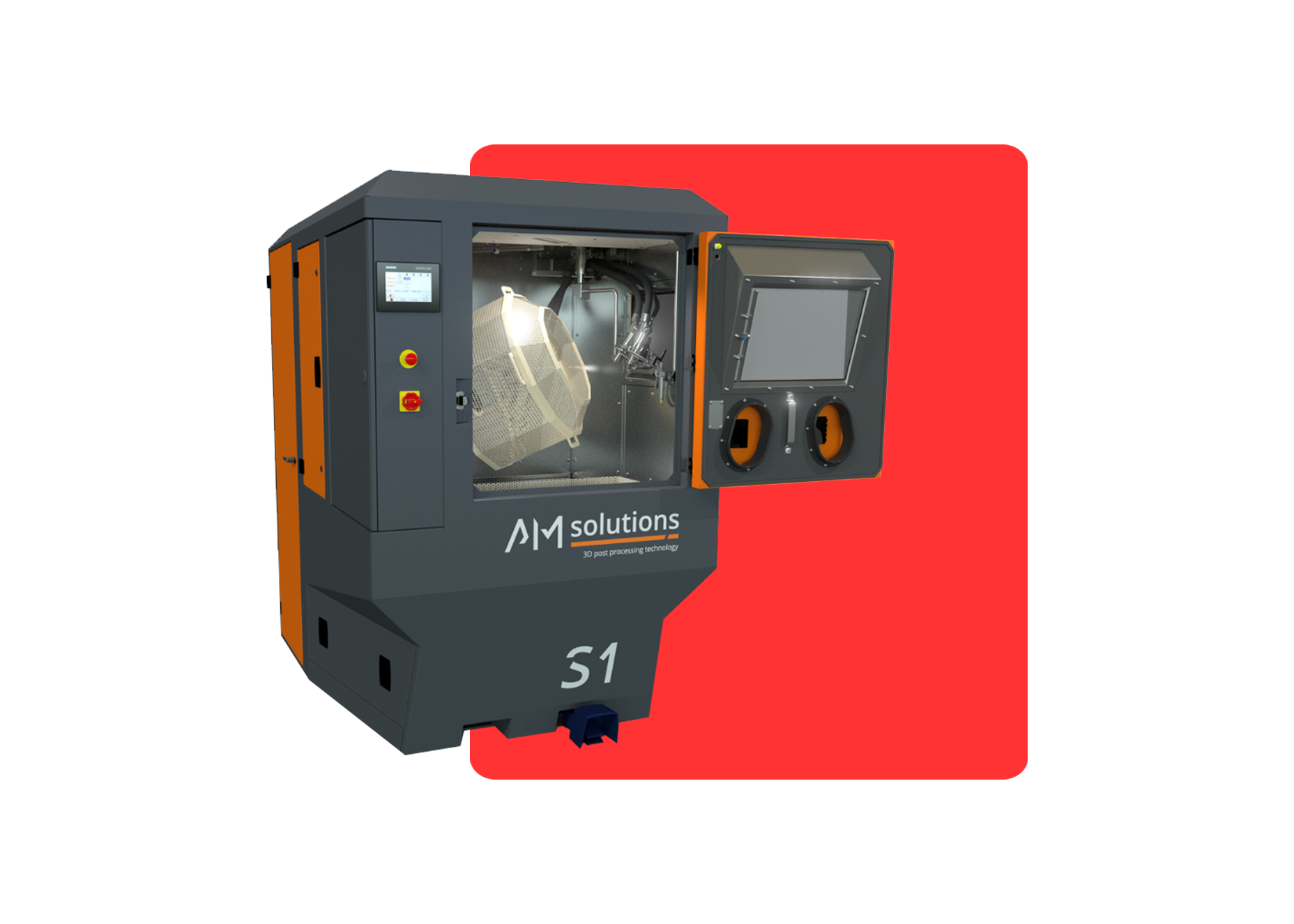

🔄 Vibro Polishing

Using abrasive media in a vibratory tumbler, vibro polishing smooths and homogenises surface textures while preserving dimensional accuracy. This process delivers a uniform satin finish and removes fine build artefacts — perfect for MJF and FDM parts requiring consistent surface quality or pre-treatment before coating or painting.

⚙️ Shot Peening / Bead Blasting

Shot peening (or bead blasting) exposes parts to high-velocity media to refine surface texture, relieve stress, and improve fatigue resistance. It produces a smooth matte finish with subtle texture that’s ideal for functional prototypes, tooling, or industrial components requiring improved surface uniformity and strength.

🎨 Painting & Surface Coating

RYSE 3D offers custom painting, dyeing, and coating services to elevate printed parts to production-quality appearance. From automotive-grade paints and colour matching to functional coatings such as anti-static or chemical-resistant finishes, our painting process ensures a professional, long-lasting surface suited to display, testing, or final assembly.

Still have some questions?

Work with RYSE 3D’s specialists to turn your designs into production-ready parts. From material advice to scalable manufacturing, our team will help you make stronger, faster, and more efficient with HP Multi Jet Fusion.