PETG

PETG (Polyethylene Terephthalate Glycol) is a high-performance thermoplastic designed for durability, ease of printing, and real-world performance. It combines the best of both PLA and ABS: low warpage and ease of use, with superior strength, chemical resistance, and toughness.

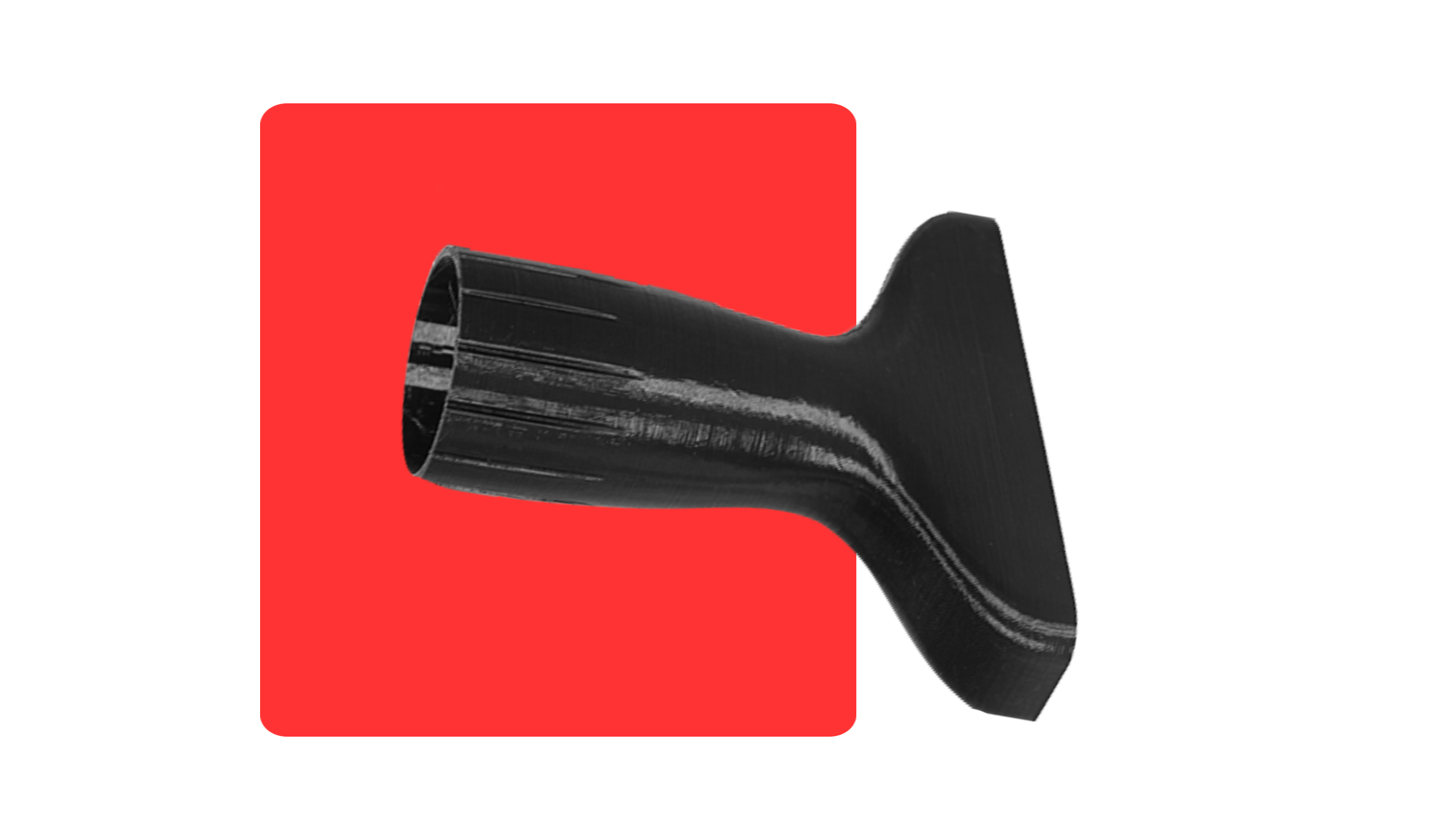

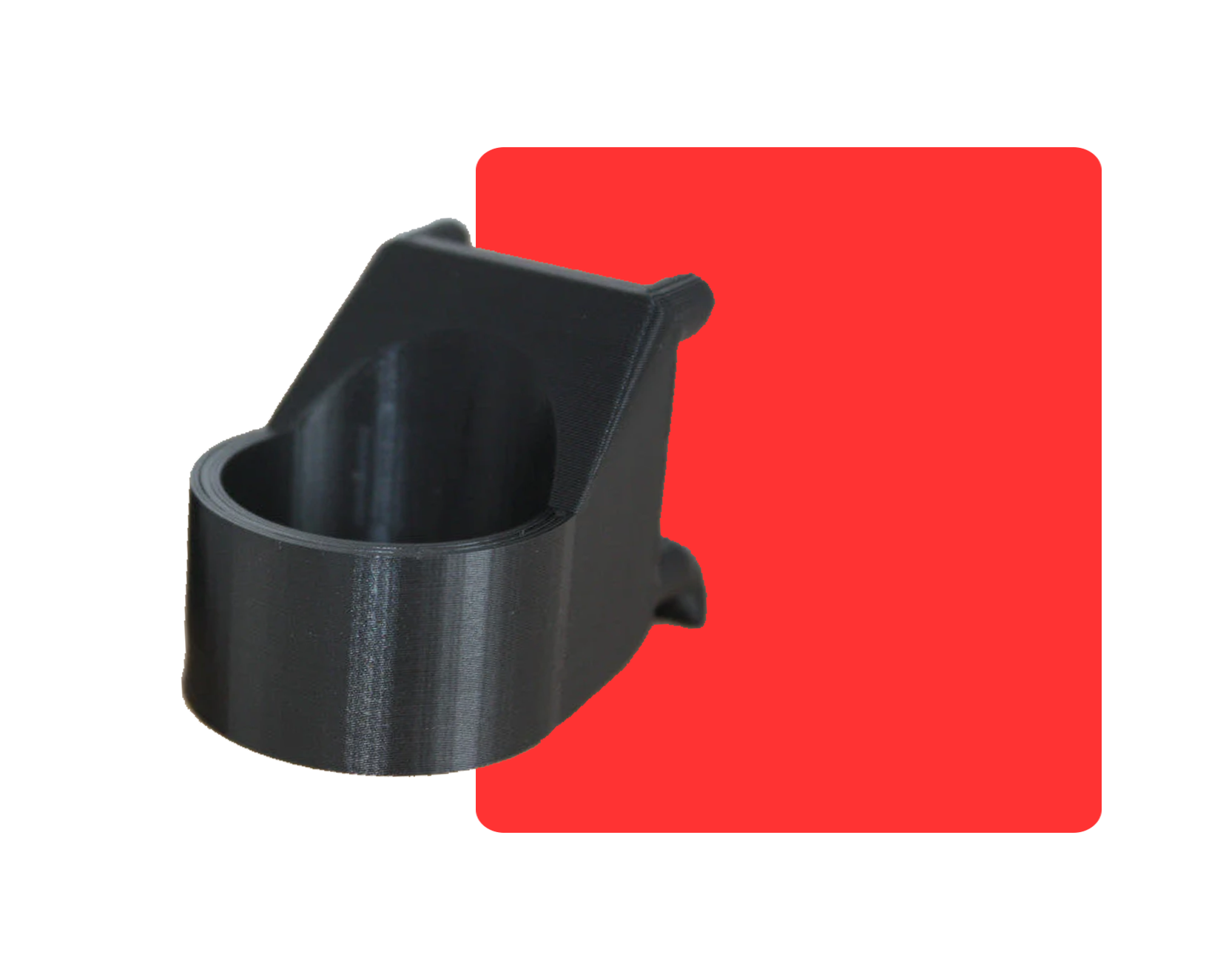

PETG produces parts with good layer adhesion, reliable dimensional accuracy, and resistance to moisture and chemicals. It performs well in functional prototypes, mechanical parts, and even semi-exposed environments.

Due to its balanced properties, PETG is ideal for functional parts, housings, mechanical components, and medium-duty end uses where strength, finish, and reliability matter.

Max Print Volume 500 x 500 x 700mm

PETG - Key Technical Specs

Material Type: PETG (Polyethylene Terephthalate Glycol)

Technology: FDM

Colour: Black

Finish Options: Vibro Polished | Vapour Smoothed

Heat deflection temperature: 69°C

Elongation at break: 8.6%

Tensile strength: 34 MPa

Tensile modulus: 1810 MPa

Ideal Applications

PETG is an ideal choice for:

- Functional prototypes and mechanical parts

- Industrial housings, enclosures, and panels

- Fluid or chemical containers and components

- Fixtures, jigs, and production aids

- Consumer product casings and appliance parts

- Automotive interior and under-hood components

✅ In summary:

PETG offers strong, stable, and chemical-resistant performance with excellent printability and finish. Perfect for functional prototypes, housings, and end-use parts, it combines strength, flexibility, and accuracy making it one of the most versatile FDM materials for industrial and engineering use.

Built on Industry-Leading Machines

At RYSE 3D, our LANDR industrial FDM systems deliver production-grade parts with exceptional accuracy, surface quality, and mechanical strength. Designed and built in the UK, they offer unmatched material freedom from standard polymers to advanced carbon- and glass-filled composites.

Compared to traditional systems, LANDR printers achieve higher part performance, lower running costs, and true scalability making them ideal for functional prototypes, tooling, and end-use production.

Post Processing

Vapour Fusing Available

Still have some questions?

Work with RYSE 3D’s specialists to turn your designs into production-ready parts. From material advice to scalable manufacturing, our team will help you make stronger, faster, and more efficient with HP Multi Jet Fusion.