PP (Polypropylene)

Polypropylene (PP) is a durable, low-density polymer prized for its flexibility, fatigue strength, and outstanding chemical resistance. Naturally lightweight and hydrophobic, PP is ideal for applications where repeated flexing, chemical exposure, or impact durability are essential.

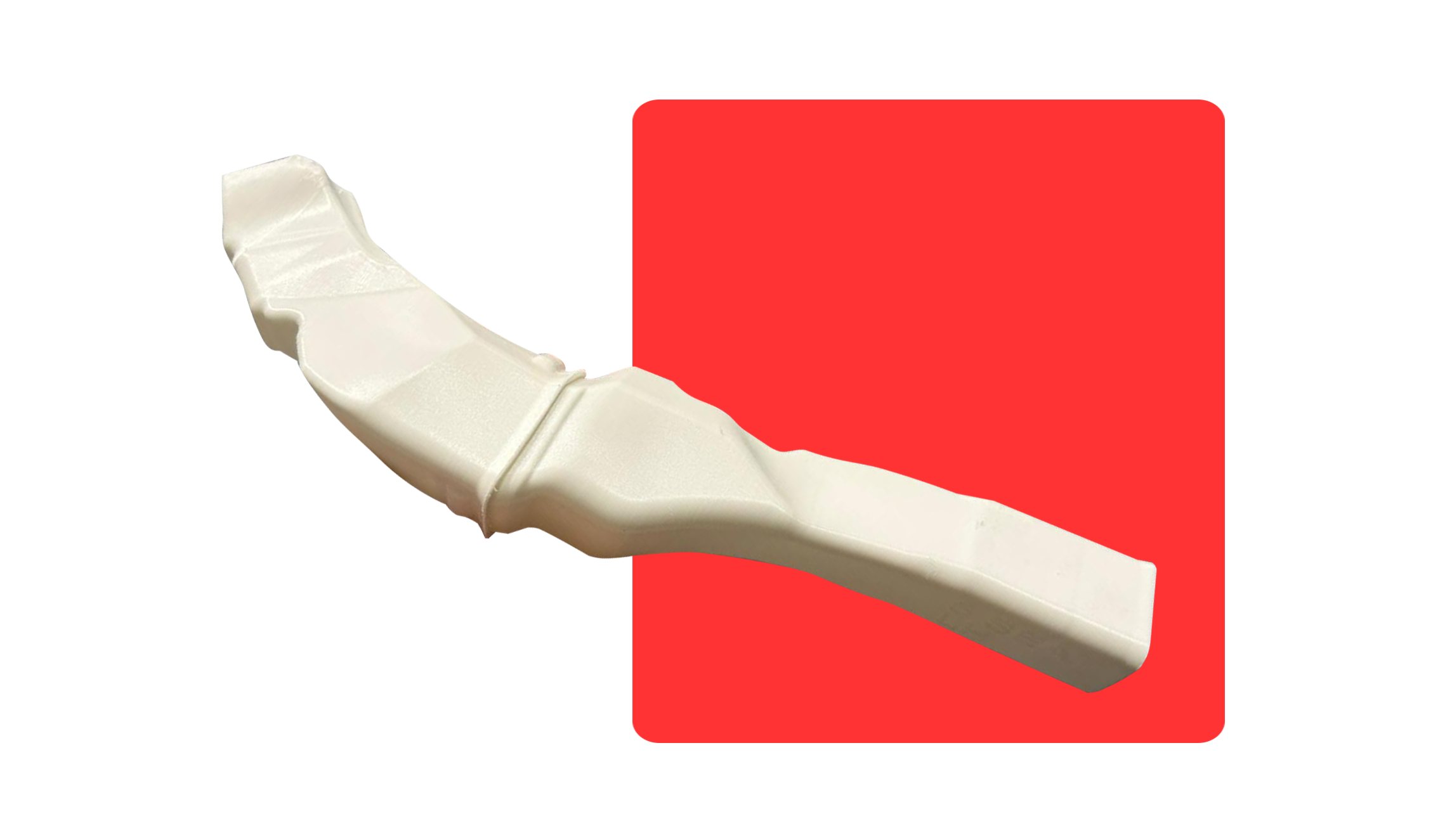

PP delivers functional, semi-flexible parts with excellent resistance to oils, solvents, and moisture all while maintaining a clean, professional surface finish. Perfect for automotive, industrial, and consumer applications, it’s the go-to choice for living hinges, snap-fit joints, fluid housings, and lightweight end-use components that need to perform reliably under real-world conditions.

Max Print Volume 500 x 500 x 700mm

PP (PolyPropylene) - Key Technical Specs

Material Type: PP (PolyPropylene)

Technology: FDM

Colour: Black, White

Finish Options: Vapour Smoothed

Heat deflection temperature: 80°C

Elongation at break: 200%

Tensile strength: 26 MPa

Tensile modulus: 1200 MPa

Ideal Applications

- Living hinges & flexible joints

- Snap-fit parts & connectors

- Fluid and chemical containers

- Automotive clips, ducts & interior fittings

- Protective covers, housings & cases

- Consumer packaging & prototype

- Industrial parts in contact with fluids or chemicals

✅ In summary:

Lightweight, flexible, and chemically resistant — Polypropylene (PP) is ideal for functional parts that need to bend, snap, or withstand harsh environments. Perfect for living hinges, fluid containers, and automotive components, PP offers durability, fatigue resistance, and low moisture absorption in a clean, professional finish.

Built on Industry-Leading Machines

At RYSE 3D, our LANDR industrial FDM systems deliver production-grade parts with exceptional accuracy, surface quality, and mechanical strength. Designed and built in the UK, they offer unmatched material freedom from standard polymers to advanced carbon- and glass-filled composites.

Compared to traditional systems, LANDR printers achieve higher part performance, lower running costs, and true scalability making them ideal for functional prototypes, tooling, and end-use production.

Still have some questions?

Work with RYSE 3D’s specialists to turn your designs into production-ready parts. From material advice to scalable manufacturing, our team will help you make stronger, faster, and more efficient with HP Multi Jet Fusion.