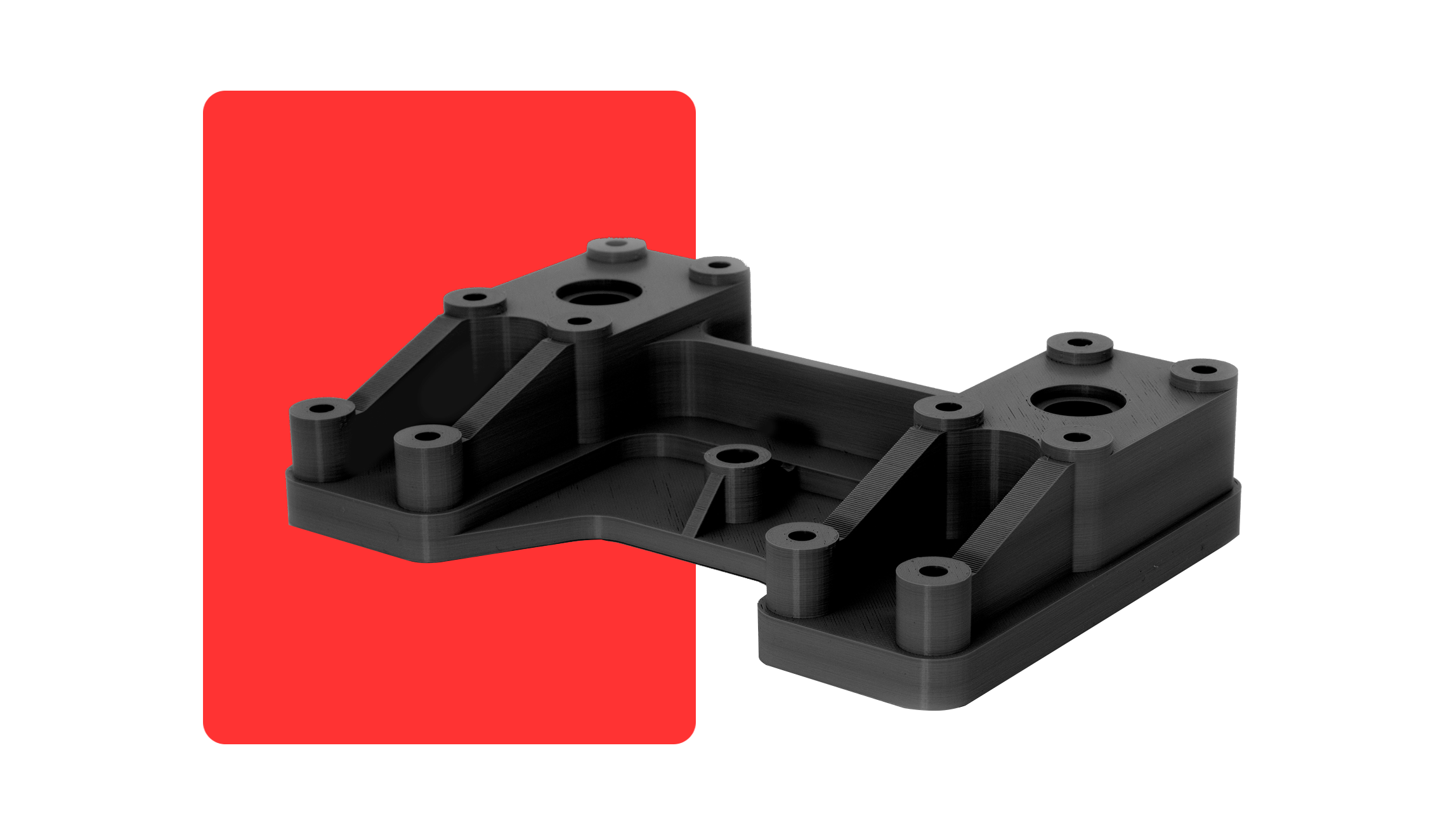

FR V0 PC-ABS

FR V0 PC-ABS is a halogen-free, flame-retardant blend of polycarbonate (PC) and ABS engineered to meet UL94 V0 self-extinguishing standards. It combines the mechanical strength, thermal resistance, and dimensional stability of PC flexibility of ABS, delivering parts that are not only tough and heat resistant but also fire-safe.

With excellent interlayer adhesion, a clean glossy or satin finish, and stable printing performance, FR V0 PC-ABS enables production of functional and safety-critical parts where flame safety is required making it suitable for many demanding environments.

Ideal for electrical enclosures, power tool housings, automotive under-hood parts, connectors, and other components where fire resistance, strength, and precision are essential.

Max Print Volume 500 x 500 x 700mm

FR V0 PC-ABS - Key Technical Specs

Material Type: FR V0 PC-ABS (UL94 V0 Flame Retardent Acrylonitrile Butadiene Styrene)

Technology: FDM

Colour: Black

Special Feature: UL94 V0 Flame Retardancy

Heat deflection temperature: 95°C

Elongation at break: 4%

Tensile strength: 45 MPa

Tensile modulus: 1990 MPa

Ideal Applications

FR UL94 V0 PC-ABS is an ideal choice for:

- Electrical housings & enclosures

- Automotive under-hood components

- Power tool and appliance casings

- Aerospace and transport interiors

- Industrial equipment & control panels

- Functional prototypes

✅ In summary:

FR V0 PC-ABS is a flame-retardant, high-strength engineering blend that combines polycarbonate’s toughness with ABS’s processability. Meeting UL94 V0 fire-safety standards, it delivers rigid, heat-resistant, and dimensionally stable parts ideal for automotive, electrical, and industrial applications where safety and performance cannot be compromised.

Built on Industry-Leading Machines

At RYSE 3D, our LANDR industrial FDM systems deliver production-grade parts with exceptional accuracy, surface quality, and mechanical strength. Designed and built in the UK, they offer unmatched material freedom from standard polymers to advanced carbon- and glass-filled composites.

Compared to traditional systems, LANDR printers achieve higher part performance, lower running costs, and true scalability making them ideal for functional prototypes, tooling, and end-use production.

Still have some questions?

Work with RYSE 3D’s specialists to turn your designs into production-ready parts. From material advice to scalable manufacturing, our team will help you make stronger, faster, and more efficient with HP Multi Jet Fusion.