Trusted by Industry from Prototype to Production

What is RYSE 3D's Mission?

Making 3D printing accessible for real production. Faster, smarter, and more sustainable.

We exist to bridge the gap between prototyping and true manufacturing, giving engineers and businesses the power to produce end-use parts without tooling, delays, or waste. By combining advanced materials, industrial-scale capability, and award-winning British innovation, we enable companies to manufacture locally, reduce costs, and shrink their carbon footprint. RYSE 3D is redefining what’s possible turning digital designs into production-ready components that move industries forward.

Our Services

PPAP Approved Automotive Parts

Production 3D Printers

Materials Available

Average Delivery from Order

Discover our Materials

Discover RYSE 3D’s full range of advanced polymers. Engineered to turn ideas into production-ready parts.

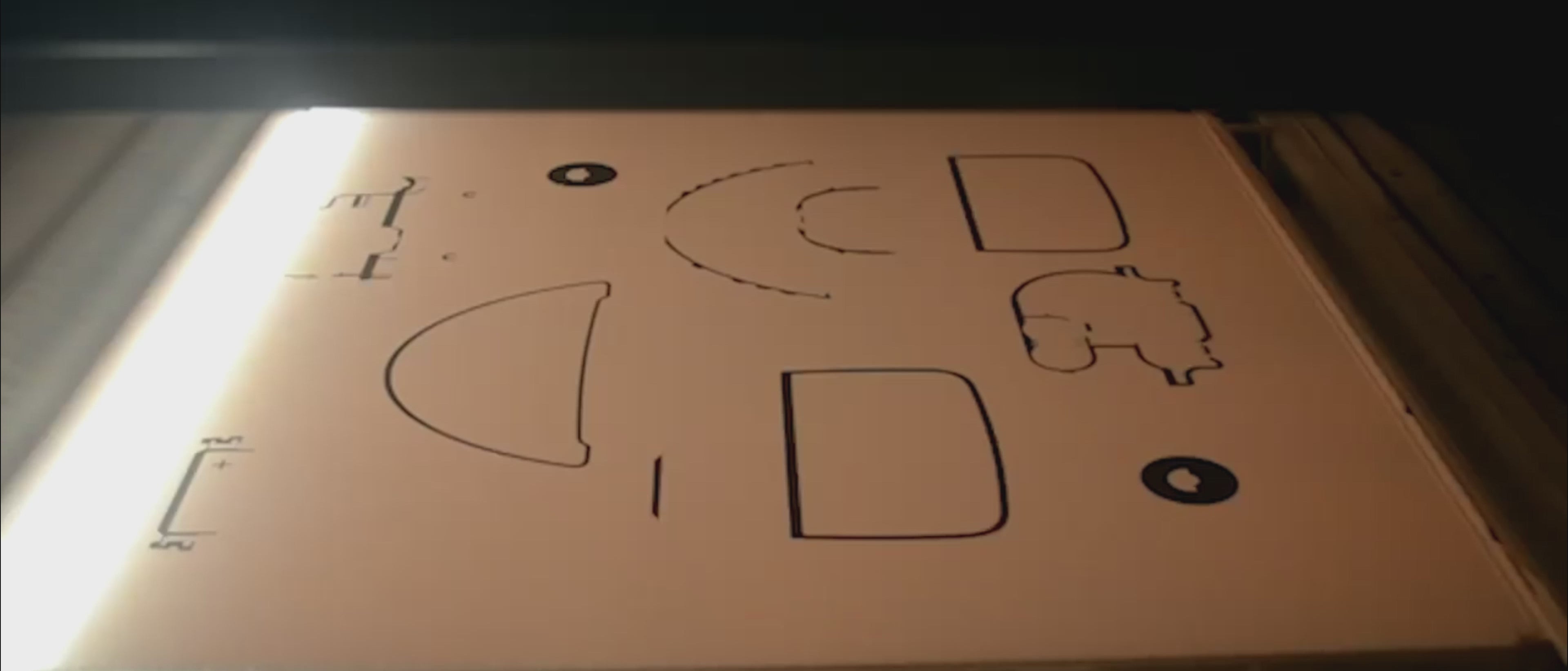

MJF - PA12, PA11 High detail Parts

Our MJF (Multi Jet Fusion) production line delivers high-precision, end-use polymer parts using advanced HP additive-manufacturing technology. It’s designed for customers who need accurate, repeatable, and production-ready components straight off the printer.

At RYSE 3D, we run HP PA11 and PA12 materials to suit a wide range of functional applications:

- PA 11 (Bio-based Nylon 11) – High ductility, excellent impact resistance, and superior fatigue performance. Ideal for automotive interiors, snap-fit parts, protective housings, and flexible clips.

- PA 12 (Nylon 12) – Outstanding dimensional stability, fine surface finish, and durability under load. Perfect for enclosures, manifolds, tooling, and low-volume production parts.

Our in-house finishing options include bead blasting, dyeing, vapour fusing, machining, and inspection, ensuring every component meets production standards.

Max Part Size 380 x 380 284mm

FDM - High Performance Large Fromat Parts

At RYSE 3D, our FDM manufacturing service uses Industrial printers to produce strong, functional parts directly from CAD data with no tooling or long lead times. Ideal for prototypes, jigs, fixtures, and full-scale production components.

We print in ABS, ASA, PETG, Nylon (PA6, PA-CF, PA-GF), Polycarbonate, and TPU + more, as well as recycled pellet materials for sustainable, high-volume output.

Whether it’s carbon-fibre tooling, durable housings, flexible seals, or structural automotive parts, our FDM process delivers tough, production-ready results at a fraction of the cost of traditional manufacturing.

Max Part Size 500 x 500 x 700mm

Post Processing

Vapour Fusing Available